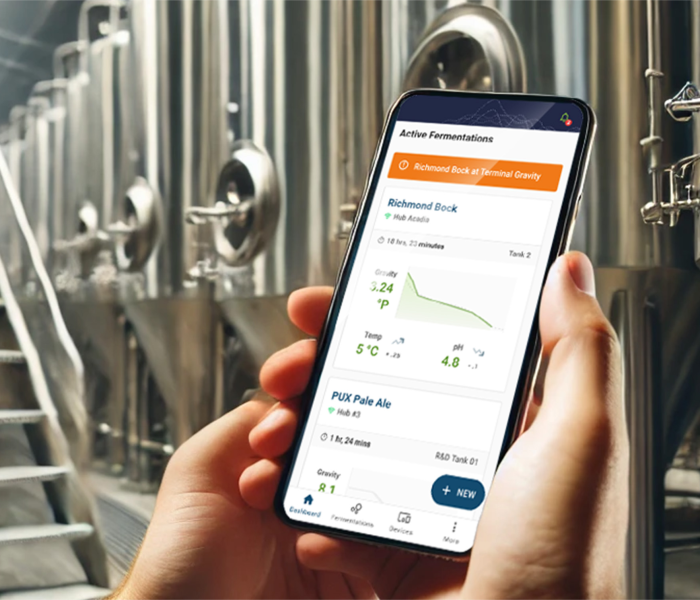

Every brewer knows that no two fermentations are the same — and that one missed reading or drowsy weekend check-in can make the difference between your best batch and a costly drain pour. The Sennosystem gives brewers, winemakers, and producers of distilled spirits, cider, kombucha, and other beverages the precision and confidence to keep every fermentation on track. Powered by AI-driven sensing technology, it automatically delivers real-time data and actionable insights to help modern beverage makers scale efficiently and maximize profitability.

The Challenge: Brewing by Feel in a Data-Driven World

Brewing blends science and creativity. Without real-time insights and the right tools, seasoned brewers face challenges. Whether you’re a hands-on brewer or running a growing production team, today’s brewing challenges share the same roots.

The Solution: One Connected Platform

Traditional brewing and beverage fermentation monitoring is slow, manual, and often reactive. At Sennos, we’ve built a platform that replaces guesswork with clarity. The Sennosystem unites three powerful technologies into one seamless ecosystem in real time so you can catch issues early, waste less, and scale with confidence with predictive AI insights for consistent quality and taste.

SennosM3: In-Tank, Multi-Parameter Sensing

Real-time data for every batch:

- Measures gravity, pH, pressure, temperature, dissolved oxygen, conductivity, and ambient pressure and ambient temperature.

- Real-time monitoring tracks fermentation as it happens — not hours later.

- Modular design supports multiple needs and easy upgrades.

The Impact: Real Results for Real Breweries

Breweries using the Sennosystem report:

fewer manual sampling rounds

reduction in cellar labor

fewer product losses thanks to early detection and smart alerts

system uptime across active fermentation batches

Supporting Brewers of Every Scale

Small Craft (1k–5k bbl)

Core Benefit: Remote visibility & automation

Key Outcome: Save time and weekends

Medium Craft (5k–15k bbl)

Core Benefit: Data-driven process scaling

Key Outcome: Consistent growth with fewer staff

Large / Regional (15k–100k bbl)

Core Benefit: Predictive QC & uptime monitoring

Key Outcome: Continuous production confidence

Customer Success Stories

See how Western Red Brewing uses Sennos to perfect every pour.

Explore how Denali Brewing Company elevated beer quality using Sennos solutions.

Learn how Terrapin Beer Co harnessed real-time brewing data for consistency.

Why Sennos

Trusted by Brewers. Built by Experts. Designed for What’s Next.

Sennos isn’t just an industry supplier. We’re a team of craftspeople, innovators, engineers, and scientists on a mission to transform brewing as we know it. We speak your language, respect your craft, and back it up with real-world results.

Pioneers in Fermentation Monitoring

Founded in 2017, Sennos has led the charge in fluidic sensing and real-time analytics for fermentation environments. Our patented in-tank sensor array and AI-driven cloud platform were designed specifically to address the challenges breweries face every day, from batch inconsistencies to labor-intensive sampling and tank downtime.

Built by Brewers, for Brewers

We know beverage fermentation because we’ve lived it. Our team includes former brewers, fermentation scientists, data engineers, and Certified Cicerones who understand the pressure of hitting flavor targets, maintaining beverage consistency, minimizing product loss, and keeping tanks moving.

We’ve combined hands-on brewing experience with cutting-edge tech to build brewing equipment that gives you clear, actionable insights to fine-tune every batch and run a more efficient business.

We’re Your Partner

Our commitment to improving your brewing and beverage-making process doesn’t end at installation. Sennos offers dedicated support, ongoing platform updates, and a collaborative approach to innovation. We work closely with each of our customers to understand their goals, refine their processes, and scale their business.